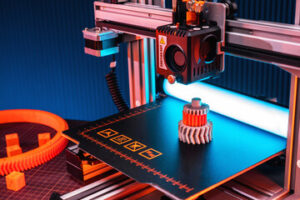

3D printing allows a person to create a physical object from a digital model. This is accomplished by using an extrusion process to layer materials based on the spatial dimensions of the computerized data file.

The 3D printing process builds a three-dimensional object by adding material layer by layer. This is unlike traditional machining, casting and forging processes where material is removed from a stock item or poured into a mold and then shaped with tools like hammers and dies. This is why it’s also referred to as additive manufacturing. Contact By3Design for professional help.

Before a model can be printed, the design must be created in 3D modeling software. This step is important in ensuring that the design meets your functional requirements. It is also important to verify that the model is compatible with the printing technology selected for your project. For example, some materials, such as metals and ceramics, require specific 3D printing processes such as Selective Laser Sintering (SLS) or Direct Metal Laser Sintering (DMLS).

Once the model is ready to print, slicing software is used to translate the 3D modeling file into instructions that the printer can understand. This step is important for ensuring that the print will be free of errors, such as thin walls and unsupported areas, and is optimized for the capabilities and limitations of the printer.

A wide range of plastics, including Polylactic Acid (PLA), is used in most consumer 3D printers. PLA is a biodegradable polymer derived from renewable resources, such as corn starch or sugarcane, making it environmentally friendly. PLA prints are not as strong as other materials, but are ideal for applications that do not require the use of a durable finish.

Other materials, such as metals and ceramics, can be printed with more advanced technologies, such as Stereolithography (SLA) or Selective Laser Sintering (SLS). Both of these methods fuse powdered materials using a laser to create solid objects. These processes offer higher precision and smoother surfaces than other 3D printing processes.

Once a part is printed, it can be further refined and optimised by post-processing. During this step, the part is heat and chemically treated to improve the mechanical properties of the finished product. This process can also help remove any remaining support structures and to make the surface of the finished part smoother.

Materials

The materials used in 3D printing are not only what determines the color and appearance of an object, but also play a crucial role in its strength, durability, heat resistance, flexibility and more. Understanding the range of materials available will help you make the best choices for your needs.

There are many different types of 3D print materials, with the most popular being plastics like polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). Both offer good durability and can be printed in multiple colors. They are also able to accept paint and super glue, making them great for artistic models.

In addition to plastic, metals like stainless steel can be used for the fabrication of functional prototypes and end-use parts in the aerospace, automotive production and medical industries. Stainless steel can withstand high temperatures and offers excellent corrosion, fatigue, wear and impact resistance. It is also very durable and demonstrates high strength, ductility and tensile modulus.

Resins and powders are another category of materials that can be used for 3D printing. These materials are typically cured in an ultraviolet light to create a solid, hardened object that can then be finished using sandpaper or steel wool to smooth the surface. Resins are primarily used for models and functional prototypes, while powders can be utilized for a variety of applications including casting, molding and machining.

There are other 3D printing material options like ceramics, which are a good choice for parts that need to be resistant to heat and chemicals. They can also be printed at the nanoscale, providing improved protection and structural integrity for microelectronics.

Whether you are creating an artistic model, a prototype or an actual part for use in industry, a successful print depends on the quality of the material used. Strength and durability are important qualities, while flexibility and thermal stability are necessary for parts that will see significant use.

The selection of a suitable 3D printing material will depend on the application, and will often be determined by the manufacturer. For example, a professional printing service will have access to a wide range of materials, allowing them to tailor the experience and outcomes for their customers. This could include everything from a simple photograph to a complex medical device.

Design

Printing allows for design iterations to be made quickly and efficiently, which reduces the overall time from initial concept to end-use product. 3D printing also enables engineers to test and prototype parts that would not be possible or cost-effective using traditional methods.

To maximize the effectiveness of 3D printing, designers must understand and apply the principles of Design for Additive Manufacturing (DfAM). These include design for strength, size, and weight; geometry optimization; material characterization; and part finishing.

The types of materials used in 3D printing vary widely. They include plastics such as polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS); composites such as carbon fiber/PLA; and bio-based materials such as cellulose acetate and nano cellulose. Many of these materials have unique properties that make them ideal for specific applications, such as heat and chemical resistance.

A variety of different 3D printing processes are available, from industrial-scale machines to desktop units that can produce one part at a time. The choice of process depends on the size, complexity, and desired quality of the printed part. Some printing processes require post-curing or annealing, which may affect final mechanical properties and appearance.

Other important considerations include the ability of the printer to operate in an environment that meets its safety requirements. For example, a 3D printer operating in an area where combustible dust is present must have intrinsically safe electrical construction and a filtration system to protect users from exposure.

In addition, safety considerations for each type of printing process differ. For instance, FDM/FFF and SLA printers can generate contaminating fumes that require special ventilation and safety precautions. EHS should evaluate each printing process to determine the level of hazard associated with it.

3D printing is becoming more common in professional and recreational applications. Lawyers use printed prototypes to make courtroom evidence more tactile, fashion designers create new textiles for the runway, and musicians experiment with new instruments. Art activists use 3D printing to reproduce historic artifacts in regions prone to destruction, and students explore anatomical and molecular structures through the physical touch of a 3D printed model.

Printing

3D printing, also known as additive manufacturing, turns a digital model into a solid three-dimensional physical object by adding material layer by layer. There are a wide variety of 3D printing processes and materials but they all share one key element: computer-aided design, or CAD. Engineers use CAD programs to create a three-dimensional representation of the desired object and then translate it into a series of two-dimensional “slices” of the object and instructions on how to solidify starting materials on each slice.

After the CAD file is ready, it’s sent to a piece of software called slicing software, which transforms it into a set of instructions for the printer to follow. This process determines factors such as the thickness of each layer, how long it will take to print and how much material will be used.

Once the slicing software has finished, the file is sent to the printer, which begins printing the object in layers, until it is complete. The resulting object may require post-processing, such as removal of support structures and excess material, surface finishing and further sintering or heat treatment, to ensure the final product has the desired appearance and strength.

Many people associate 3D printers with fun figurines and jewelry but they can be used for a wide range of professional applications as well, including creating functional prototypes for engineers and architects and producing end-use parts that replace traditional metal, plastic or wood products. 3D printing can also help improve the efficiency of manufacturing processes by replacing manual tools and methods, such as casting or forging, with automated, computer-controlled machines that can produce a large number of identical parts quickly.

3D printing requires specialized equipment and safety precautions, so it is important to plan ahead when using this service. Patrons must submit print requests at least 7 days in advance of when they need the item to allow time for processing and to ensure the printer will be available for use. During the printing process, it is imperative to remain in the lab area for safety reasons. Printers generate high temperatures during operation, which can cause burns or scalds if the user comes in contact with them.